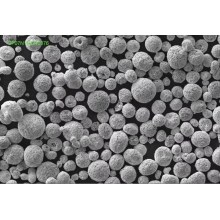

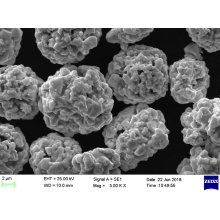

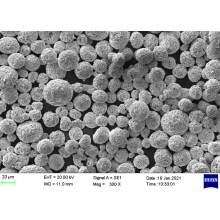

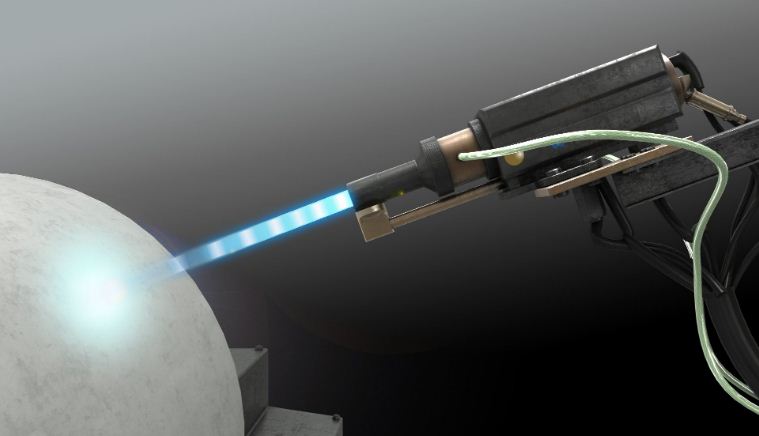

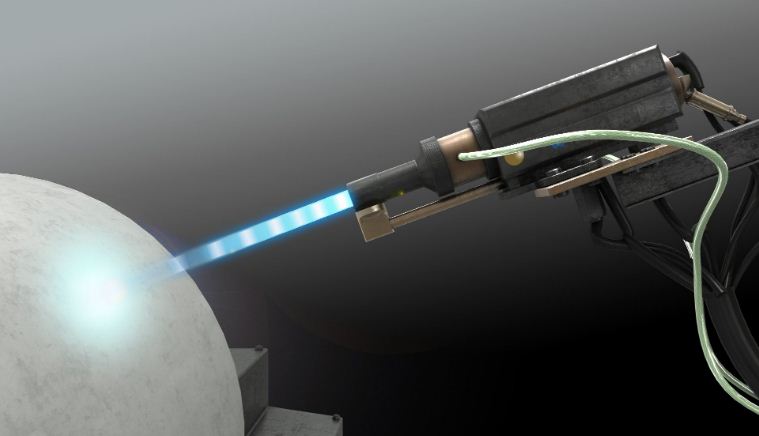

XTC provide alternative choice for Steel rolls coatings. And WC-9Co-5Cr-1Ni 15-38um Thermal Spray Powder is generally best using High Velocity Oxygen Fuel (HVOF) spray. Which

Show good corrosion resistance and toughness than WC-Co coating, Superior oxidation resistance and corrosion resistance than WC-Co coating. Apply to gate value and relevant component. Max. operating temperature 500°C. The HVOF Powder like gp09cn could be considered as one choice for different kinds of the thermal spray applications to instead of the tradtional WC coating powder in particular fileds.

Using good raw material to make the better powder coating. And develop the coating peforamnce properties. The GP09CN HVOF Tungsten Carbide Coating shows good properties in different kinds of areas. XTC specially recommend GP09CN in some particluar using field like steel, Iron making, Gate Valves, etc.,

Thermal spraying technology is widely used in the engineering field due to its great advantages. This powder contains development trends of thermal spraying technology, including main flame spraying technology, plasma spraying technology, supersonic flame spraying technology, etc.,

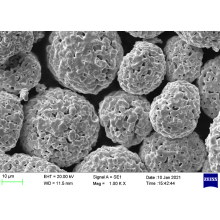

Spray System HVOF

Coating Micro-hardness 950-1350 HV0.3

Bonding Strength ≥70MPa

Porosity <1%

Deposit Efficiency 45-60%

Maximum Service Temperature 500℃

Product Categories : Thermal Spray Materials > Tungsten Carbide Powder

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now