**Product Introduction:**

GPFAT13 is a state-of-the-art **thermal spray material** engineered to deliver outstanding wear-resistant ceramic coatings. Comprised of alumina with approximately 13% titania, this **

Oxide Ceramics Powder** is specifically designed to meet the demands of high-performance industrial applications. Produced through an advanced Fused and Crushed process, GPFAT13 is ideal for applications requiring high toughness and excellent surface finishes.

**Product Description:**

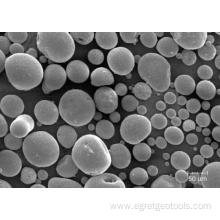

GPFAT13 represents a breakthrough in thermal spray technology, offering superior flow properties and deposit efficiencies even at high feed rates. Its unique spheroidal morphology ensures consistent feeding during spraying, resulting in coatings with homogeneous phase distributions and smooth surface finishes. The microstructure of GPFAT13 significantly enhances deposit efficiency, reducing processing time and minimizing overall waste.

**Key Features:**

- **High Toughness**: While maintaining impressive wear resistance, GPFAT13 coatings exhibit higher toughness compared to those with lower titania content, making them ideal for demanding applications.

- **Temperature Resistance**: Effective in environments with operational temperatures up to 540°C (1000°F), providing versatility across various industrial settings.

- **Cost Efficiency**: The improved deposit efficiency and reduced processing time translate to potential cost savings in manufacturing and maintenance operations.

- **Versatile Applications**: GPFAT13 is suitable for use in diverse industries, including petrochemicals, textiles, mechanical seals, and electrical insulation. It is particularly effective for enhancing the durability and performance of components such as pump liner seals, shafts, household equipment, textile machinery,

Composite Roller, and

Weld Materials.

**Applications:**

1. **Textile Components**: Enhances wear resistance and durability, ensuring the long-term stability of textile machinery.

2. **Petrochemical Equipment**: Provides improved wear resistance and chemical stability to pump bushings and sleeves, enabling reliable performance under harsh conditions.

3. **Mechanical Seals**: Increases wear resistance and sealing effectiveness, prolonging the lifespan of mechanical seals.

4. **Electrical Insulators**: Suitable for applications requiring chemical stability and wear resistance in electrical insulating materials.

GPFAT13 is the ideal choice for industries seeking to optimize their coating processes and extend the life of their components. Its advanced formulation ensures exceptional performance, making it a valuable asset for any application requiring high-quality thermal spray coatings.

Product Categories : Thermal Spray Materials > Oxide Ceramics Powder

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now