Here is a brief introduction about us.

Company: Luoyang Golden Egret Geotools Co., Ltd

Employees: 719

Registered Capital: USD 161,538,461.00

Our products are including: Welding Wires , Welding rods, Welding ropes, PTA powders (Nickel Based Alloy Powder, Iron Based Alloy Powder, Cobalt Based Alloy Powder, Mixed Powser), Thermal Spray Materials(Tungsten Carbide Powder, Chromium Carbide Powder, etc), Tungsten Carbide Grits, Tungsten Carbide Pellets etc.

Our company is the subsidiaries of XTC (Xiamen Tungsten Company).

XTC is the company controlled 30% high grade tungsten mineral resources in the world, and produce over 30,000 tons tungsten smelting products every year.

The employees in our group are over 14,000.

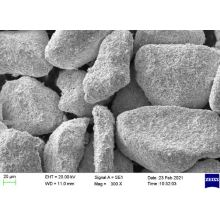

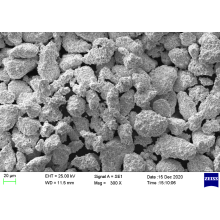

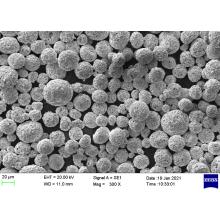

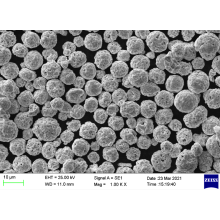

WC-12Co, available from XTC Luoyang, is a high-quality tungsten carbide-based powder designed specifically for thermal spray applications. With a composition of 88% WC and 12% Co, this powder’s medium tungsten carbide structure and particle size range of 15-45 µm make it ideal for High Velocity Oxygen Fuel (HVOF) and High Velocity Air Fuel (HVAF) spraying. The powder is manufactured through an advanced agglomeration and sintering process, resulting in an intensive coating with high bonding strength, exceeding 70 MPa, and ensuring durable performance.

Key Properties and Applications

-

Unmatched Wear and Corrosion Resistance: WC-12Co coatings provide robust abrasion and corrosion resistance, making them highly suitable for high-stress environments. This Thermal Spray Powder is commonly applied to valve parts, steel rolls, corrugator rolls, and petroleum pipeline repair, delivering a protective layer that extends the operational life of these components. Its ability to withstand temperatures up to 500°C (930°F) makes it especially valuable for industries requiring durability in extreme conditions.

-

Superior Bonding Strength and Structural Integrity: The agglomerated and sintered process used in WC-12Co production enhances the powder’s performance, creating a dense coating with minimal porosity (<0.5%) and a compact microstructure. This thermal spray material forms a strong, reliable bond, allowing it to resist corrosion, erosion, and wear effectively even in high-pressure, saline environments, such as those encountered in the oil and gas and papermaking industries.

-

Versatile Application Techniques: WC-12Co is compatible with several advanced thermal spray techniques, including HVOF, APS (Atmospheric Plasma Spray), and HVAF. Its adaptability and high coating quality make it a versatile solution, suitable for demanding applications that require both structural durability and aesthetic surface quality.

As a premier tungsten carbide powder, WC-12Co from Luoyang Golden Egret provides reliable, high-performance coatings that support the longevity of critical components across multiple industries. Its proven effectiveness in environments with high abrasion and corrosion reinforces its position as an essential material for advanced thermal spray coatings.

Product Categories : Thermal Spray Materials > Tungsten Carbide Powder

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now

Contact Now

Contact Now