1.Welding materials

In Welding, substances called filler materials or consumables are used. As the name implies, these substances provide filler or a body of molten materials that provides a strong bond to be formed between the base metals used. Most welding processes will also require some form of shielding to protect both the main components and filler from being oxidized during the process.

The type of welding materials used during welding depends on the nature of the job intended. Electrodes draw the necessary energy in order to perform welding applications. Luoyang Golden Egret Company has any kind of welding materials include CTC Welding Rod/rope, SCTC welding rod/rope, TC electronic welding rod, Ni-based welding rod, flux-cored Welding Wires, solid welding wires and etc.

Welding can be applied in different kinds of industries such as building and construction, oil and gas, marine, power generation, steel, mine tools, automobile, transportation and etc.

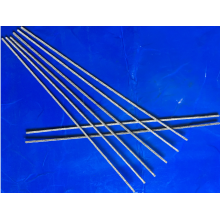

2. Welding rod

1)Cast tungsten carbide based tubular rod

The hard phase of the rod is cast tungsten carbide which leads to higher hardness and better wear-resistance.

Wear resistance: the wear resistance is 6-7 times better than others. Tested by ASTM G65

Mainly used for Mining machinery, Geological tools, Petroleum drilling tools etc, by Oxy-Acetylene with weak carburizing flame.

Product recommendation:

GT1103 (CTC, 60-80 mesh),

GT1103-1(CTC, 20-30 um),

GT1103-2(CTC, 40-60 um)

2)The hard phase of tube rod is Carbide Pellets which leads to higher impact resistance and better wear resistance than CTC cloase rod.

Wear resistance: the wear resistance is 6-7 times better than others. Tested by ASTM G65 wear test.

Mainly used for mining machinery. Geological tools etc; by Oxy-acetylene with weak carburizing flame.

Product recommendation:

GT2102 (Cemented carbide grit, 30-60mesh)

GT2102-2(Cemented carbide grit, 30-40mesh)

GT2102-3(Cemented carbide grit, 40-60mesh)

3)Tube rod is composited by Cemented Carbide Pellets, Spherical CTC and CTC. The layer has higher impact resistance, better wear resistance and good fluidity than other rods.

Wear resistance: the wear resistance is 6-7 times better than others. Tested by ASTM G65.

Mainly used for oil method drill bits, such as Tri-cone bit, Steel tooth bit, PDC bit, etc. By Oxy-Acetylene with weak carburizing flame.

Product recommendation:

GT3302 (carbide pellets, 20-40mesh)

GT3302-1(carbide pellets, 14-40um)

4)The hard phase of the rod is monocrystal WC, the welding layer has a higher wear resistance and better impact resistance.

The wear resistance is 6-7 times better than others, tested by ASTM G65 method.

Mainly used for the repair and strength for oil drills bits, such as PDC bit diameter holding by Oxy-Acetylene with weak carburizing flame.

Product recommendation:

GT4104 (Monocrystal WC, 80-200mesh)

3. Welding Rope

Made form mixture of CTC and self-fluxing nickel alloy covering on nickel wire. The CTC is in spherical or irregular with good wear resistance; the nickel alloy is in spherical or nearly spherical shape with good wettability and erosion resistance and better corrosion resistance than tubular rod.

Recommend to use Petroleum drilling tools, Concrete mixing blade, Mud pump, Coal sluice, Coal drill pipe, Tunnel drilling machinery etc.

By Oxy-Acetylene Welding with weak carburizing flame.

Product recommendation:

GS110450N (CTC, 4mm, HRC 47-55)

GS110550N (CTC, 5mm, HRC 47-55)

GS110650N (CTC, 6mm, HRC 47-55)

4. Welding Bar

The rod is sintered by CTC and Ni-based powders. The CTC(Cast Tungsten Carbide) is in irregular or spherical shape with better wear resistance and the nickel alloy is in spherical or nearly spherical shape and has good wettability with cast tungsten carbide. The cladding layer has a higher impact resistance and better wear resistance.

Its wear resistance and corrosion resistance is between tube rod and flexible rope.

Mainly used on the Steel PDC bit, Concrete mixer blade, Mud pump, Miner chute, Miner drill stem and Mechanical parts of Tunnel rock drill machine etc.

Welded by Oxy-Acetylene with weak carburizing flame.

Product recommendation:

GD4025253-3(CTC, SCTC, 4*600/6*600)

GD4030303-3(CTC, SCTC, 4*600/6*600)

5. Welding wire

Intensified molybdenum titanium vanadium composite chromium carbide welding wire can improve layer`s bonding strength and tenacity. This wire can use for multilayer welding which has no peel off, and it can maintain good wear resistance under certain impact working condition.

Product recommendation:GSQD671Mo-4(1.6mm)

Medium carbon and high chromium wear resistance welding wire has a higher hardness, stronger wear resistance, and excellent toughness by adding a certain amount of molybdenum alloys and boride. It has a better impact resistance and strip resistance than high chromium cast iron type materials

Product recommendation: GSQD621Mo-4(1.6mm)

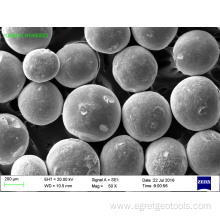

6. Tungsten Carbide Pellets

With high sphericity & excellent alloy organization, cemented carbide pellet is mainly used in welding, as an adding material of PTA Powder , Tubular Welding Rod, to improve the wear resistance of the workpieces greatly.

Product recommendation: GQ06

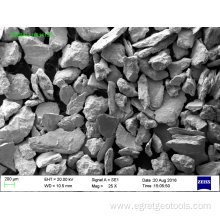

7. Tungsten Carbide Grits

Cemented carbide grit with different percent of cobalt has good abrasive resistance and is widely used for making grinding, polishing and cutting tools.

Product recommendation: GS08A

Inquiry Basket ( 0 )

Inquiry Basket ( 0 )

Contact Now

Contact Now